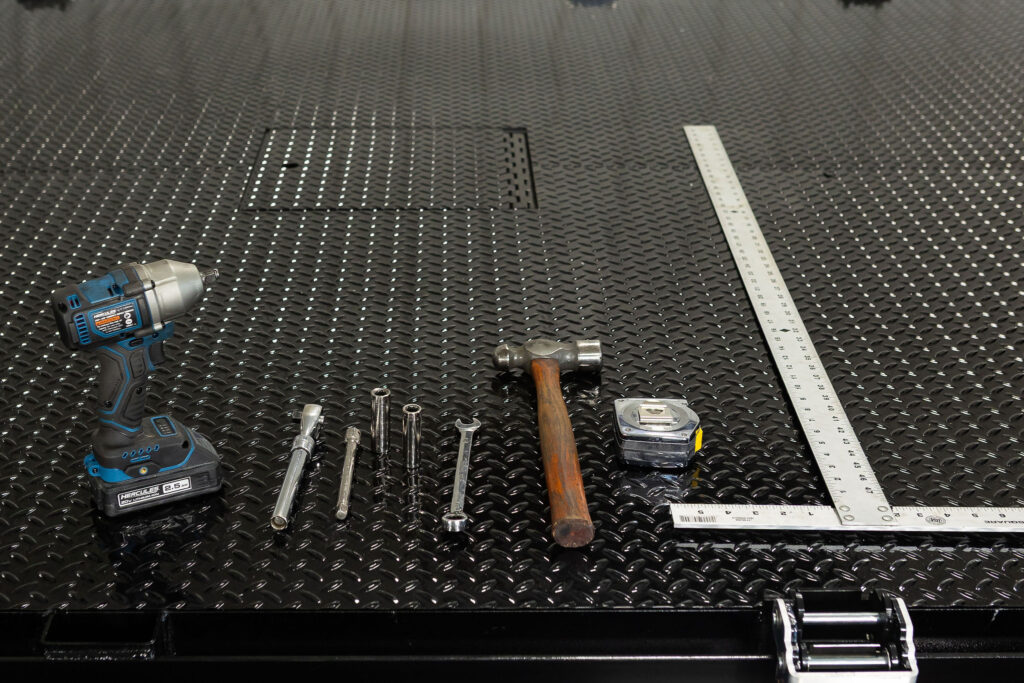

Required Tools

- 3/8” Battery Impact

- 3/8” Ratchet

- 3/8” Extension

- 9/16” Deep well socket

- 1/2” Deep well socket

- 1/2” Wrench

- Hammer

- Tape measure

- Square

- Circular saw with a carbide-tooth saw blade

Fold-Down Gate Assembly Instructions

Fold-down gates can be used as sidegates or tailgates on stright-back flatbed trucks. Follow these instructions for all fold-down gates.

Plan Layout

- Measure truckbed length.

- For dovetail truckbeds, only measure the side length.

- Determine stake position. Each gate requires a minimum of 2 stakes, this means some pockets may be empty.

- We recommend a maximum sidegate length of 8 feet. Customize your gates to shorter lengths for more flexibility.

Stake Assembly

This step is applicable for both the pre-drilled stakes and universal stakes.

- Measure truckbed pocket depth. Depth varies by manufacturer.

- Use supplied 1.5″ long, 3/8″-16 carriage bolts designed for 3″ pocket depth.

- If longer bolts are required, these can easily be purchased at most hardware stores.

- Apply push nuts to carriage bolts.

- Tip: Use a socket to apply supplied push nuts

- Check pocket alignment. Gaps can be caused by welds or burrs on truckbed pockets.

- These can be removed with a grinder or chisel. (02:30)

- Once positioned, add nuts to carriage bolts and tighten to 25lbs torque.

- Repeat for additional stakes.

- Remove protective plastic film.

Trim Slats

If you’ve ordered slat material, follow these steps for installation.

- We recommend allowing 1/2″ gap between gates with endcaps installed (3/4″ without).

- Measure slats to the desired length.

- Tip: Trim slats to length with a carbide-tooth saw blade.

Sidegate Assembly

- Align supplied fastener hardware. This slides into the narrow groove in the slat material.

- Fasten to posts with supplied washer and nuts.

- Tighten to 25lbs torque.

- Continue for additional slats.

- Install endcaps.

- Repeat for additional gates.

Mid-gate Assembly Instructions

Mid-gates can be used as a divider or lift out tailgate on dovetail truckbeds. Mid-gates require sidegates with slats.

Retainers & Brackets

- Assemble retainers (All materials supplied).

- Install 5/16″-18 knurled neck carriage bolts into the aluminum retainer with a hammer.

- Retainers fit into larger slat opening.

- Fasten mid-gate side brackets to retainers and set desired position along sidegate.

- For a liftout tailgate (great for dovetail trucks), position brackets at the end of your last gate.

- Use wrench or socket for minor adjustments and impact for final tightening.

- Tighten to 25lbs of torque.

Trim Slats & Assemble Mid-gate

- Measure and cut slats.

- Tip: Allow 1/2″ gap, 1/4″ with endcaps installed.

- Measure spacing for mid-gate stakes.

- We recommend allowing 12″ from slat ends on outside stakes.

- All mid-gates include 3 mid-gate stakes.

- Position hardware and attach stake with supplied hardware.

- Check stake alignment with a square.

- Make adjustments and tighten into position with socket.

- Repeat for additional stake.

- Tighten into place with impact to 25lbs torque.

- Install endcaps.

Mid-gate Usage

Assembled mid-gate slides into mid-gate side brackets. Mid-gates are not free-standing. They are removed by lowering one sidegate or lifting out the full mid-gate.